The term “scheduling” can mean different things to different people. To some it is more of a strategic issue. A forester may wish to answer a question: “What month do we harvest tract x?” This seemingly simple question may have many complex related variables such as standing inventory, trucking resources, weather, delivery requirements, harvest costs, and mill requirements.

To a manufacturing manager the question might be: “Which plant should make order z?” In a multi-mill setting there are many considerations. Freight cost is often a big factor, as is customer preference, inventory, manufacturing capabilities and costs as well as a myriad of other elements.

To an individual mill the question might be: “How can I make sure that all the orders ship by Friday?” In this environment sequencing, production rates, in-process inventory, yields and other elements are very relevant.

The Optware Apex System is designed in such a way that allows a comprehensive approach to scheduling plywood plants. It incorporates all of the relevant decision variables necessary to optimize the allocation of resources. Optware Apex will deliver an optimized weekly schedule as well as optimized daily and shift schedules.

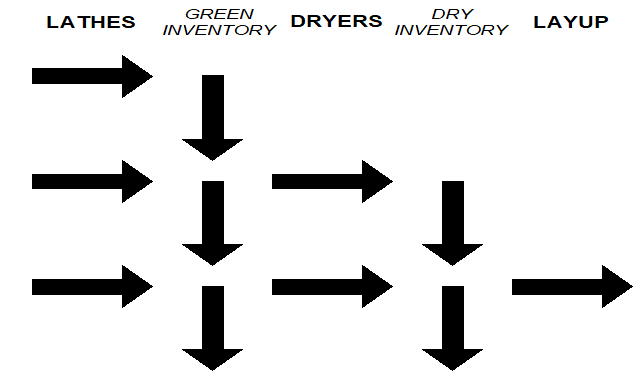

- The Apex System scope includes the entire manufacturing process with an emphasis on dryers and layup

- The Apex System considers veneer grade yields as well as panel yields through work centers as it develops an optimized schedule.

- Apex creates an optimized 7 day plan with multiple time buckets. The 7 day plan will give a broad view of orders planned to be shipped by day. The 7 day plan will consider panel, WIP and veneer inventories as well as machine center constraints. Alternatively, the time period variables can be modified to represent shifts or variable length time periods.

- The weekly schedule will consider green and dry veneer inventories, WIP panels and finished panels. The result will be a sequence of activities by work center.

- Optware Apex considers inventory limitations and delays in the process such as cool-down periods for veneers and panels

Contact Optware today to schedule a consultation

503-645-2390 | info@optware.com